Intelligent Chemistry.

Intelligent Delivery.

Science & Technology

OUR CHEMISTRY PLATFORM

EnviroKlean’s proprietary chemistry platform, EK One™, is the foundation of our disruptive approach to the treatment and management of produced water.

EK One™ was developed to take advantage of the concept of chelation, harnessing the power of the carbon atom in a revolutionary new way. EK One “molecularly wraps” Iron (Fe), NORM, and other basic elements with carbon atoms, preventing them from initiating the organic chemical reactions that create iron sulfides, TENORM, and other toxic waste by-products.

As a result of this transformative chemistry, the Iron and other elements responsible for creation of solids are returned back into solution — where they permanently reside, along with the NORM − stable, sequestered, and forever bound within the source water. By eliminating Iron-based organic reactions, EK One prevents waste solids from forming, which revolutionizes the treatment of produced water.

With EnviroKlean’s innovative approach, waste remediation and maintenance expenses are reduced, capital expenditures are lowered, and both system capacity and environmental sustainability are improved.

The EK One platform is comprised of seven core components that interact in combination with each other to solve complex water challenges and improve the health of produced water:

- CHELATORS – Impacting Iron (Fe) and NORM

- DISRUPTERS – Impacting Biofilms, Organic Materials, and Scale

- INHIBITORS – Impacting Corrosion, Scale, and TENORM

- PREVENTERS – Impacting Biofilms, H2S, Iron Sulfides, Scale, and TENORM

- PROTECTORS – Impacting Equipment and other Metal Material, both surface and subsurface

- REMOVERS – Impacting Biofilms, BSW, H2S, Iron Sulfides, Scale, and TENORM

- SCAVENGERS – Impacting H2S and Iron Sulfides

OUR CHEMISTRY DELIVERY MANAGEMENT SYSTEM

Transforming the water treatment industry takes more than better chemistry. It takes better delivery of that chemistry.

After years of experience using conventional pumps and static injection methods to deliver chemicals, EnviroKlean realized none provided the capabilities needed to optimally deliver the right chemistry at the right time, so we developed our own chemical delivery management system, EK FlowPro™.

The EK FlowPro SYSTEM consists of both an operating system and a suite of proprietary hardware solutions that manage and automate chemistry injection. EK FlowPro resolves the many challenges associated with accurately measuring, controlling, and managing the injection rates for multiple chemicals at multiple points of injection. It enables:

- CHEMICAL INJECTION AUTOMATION – remote autonomy, dynamic control, and synchronization of multiple pumps pumping multiple chemicals

- FLOW PACING – chemical injection flow for each pump varies in order to match constantly changing water volumes, enabling the PPM concentrations for each prescribed chemistry to remain constant

- DYNAMIC FLUID MANAGEMENT – continuous monitoring of ever-changing water characteristics, combined with predictive analytics enables PPM concentrations to be autonomously adjusted “on the fly” based upon the changing demands of the water

With EK FlowPro, regardless of constantly changing water conditions, targeted KPI levels can remain constant, providing assurance that optimal water conditions are continuously maintained. Fully integrated with EnviroKlean’s customer portal, EK Insight™, EK FlowPro represents the state-of-the-art for autonomous control of water chemistry injection and control.

OUR SOLIDS-FREE DISCHARGE TECHNOLOGY

Revolutionizing the recycling of produced water through patent-pending technology that eliminates the need to generate waste solids in order to remove them

Zero Solids™ is the patent-pending technology that powers the EK Zero Solids Recycle™ system. It enables produced water recycling without the need to generate solid waste, finally making the concept of solids-free discharge a reality.

Zero Solids is disrupting today’s conventional recycling methods of either dissolved air flotation (DAF) or “flock and float”, as it eliminates the need to stimulate the formation of solids in order to physically remove them. The Zero Solids technology leverages the power of chelation within chemical reactors to create beneficial reuse fluids that permanently sequester TSS, including the recycling and sequestration of the small remainder TSS captured within filtration systems, enabling produced water to be fully recycled for reuse without the need to create and then haul-off waste solids.

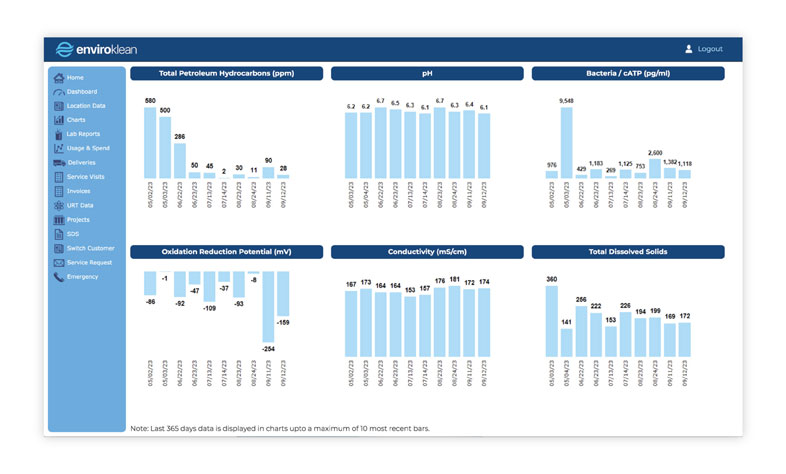

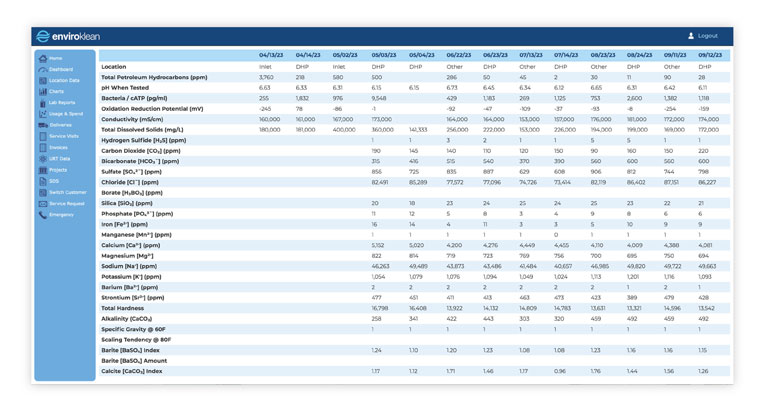

OUR DIGITAL DASHBOARD

Offers customers access to the data and analytics detailing the performance of their EK solutions from any device.

EK Insight™ offers customers access to the data and analytics detailing the performance of their EK solutions from any device. Customers receive real-time visibility into key measures including robust dashboard and reports.

PERFORMANCE REPORTS

- Chemical Spend

- Water Analysis

- Solids Analysis

- Bacteria Analysis

- Oil (TOG) Analysis

- Corrosion Analysis

RATE REPORTS

- Chemical Feed Rate (PPM/GPD)

- Influent Flow Rate (BPM/GPM)

- Effluent Flow Rate (BPM/GPM)

- Chemical Inventory Levels

- Chemical Line PSI

SITE VISIT REPORTS

- Chemical Delivery

- Chemical Refill

- Site Inspections

- Location Repairs

- Location Maintenance

With EK Insight, customers gain the peace of mind knowing their equipment is optimized and they are running at peak performance.