Improving the health of produced water.

About Us

OUR APPROACH

A Whole New Take on Wellness

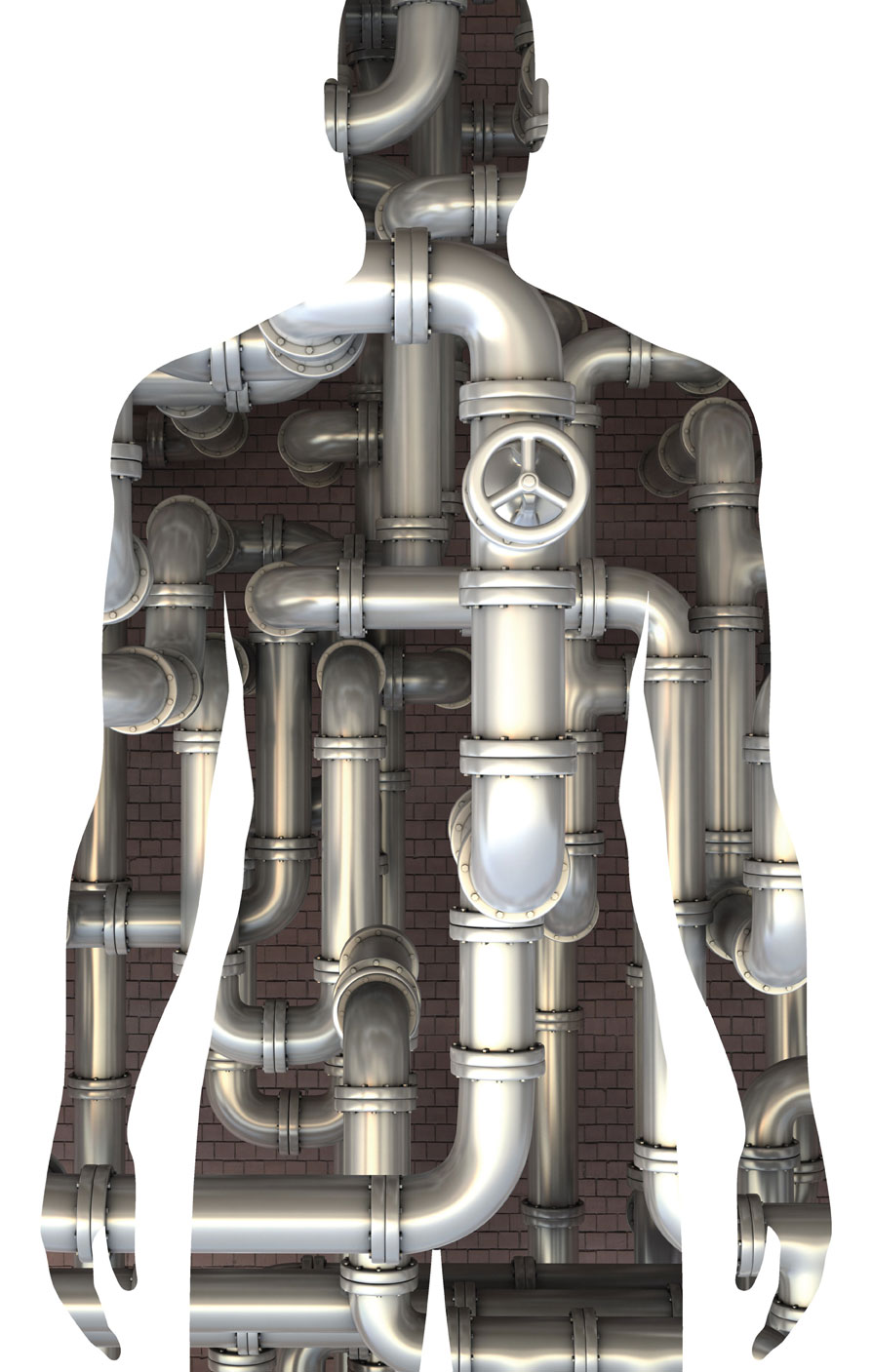

EnviroKlean takes an innovative “wellness” approach to treating water. We believe the health of a produced water system is analogous to the health of a human’s circulatory system.

Just as today’s better pharmaceuticals help prevent circulatory problems within human hearts (pumps), valves, and arteries, EnviroKlean’s better chemistry helps prevent circulatory problems within the pumps, valves, tanks, and pipes that move water through the oil and gas industry’s circulatory system.

Our preventative health approach is the opposite of today’s status quo, which relies on conventional, off-the-shelf chemistry that causes large quantities of toxic waste to form. Whether this waste forms as solids or as “plaque buildup” within the walls of pipes and other infrastructure, today’s status quo results in the need for more expensive “emergency care” to separate, remediate, and dispose of this toxic waste.

The benefits of EnviroKlean’s innovative new approach are clear:

- less toxic waste to haul off

- lower capital expenditures

- reduced operating costs

- reduced pressure levels for pipelines, batteries, and disposal wells

- increased overall system capacity

The lasting result of our “water wellness” approach is not only increased overall system capacity but also enhanced water sustainability.

SUSTAINABILITY

Water Sustainability is at Our Core

The mission of EnviroKlean is to improve the health of produced water and the midstream infrastructure that supports it. By improving the health of produced water and this midstream infrastructure, we simultaneously improve the financial and operational performance of our customers and we improve water sustainability for our world.

Water sustainability is at the core of our innovative “health and wellness” approach to water treatment. Our revolutionary chemistry platform, EK One™, coupled with our proprietary automation technologies allow us to materially improve sustainability by enabling:

- Significant reduction in toxic solids throughout batteries and SWDs, reducing the amount of toxic waste hauled to landfills

- Reduced scale-based “plaque buildup” within water pipelines, increasing the efficiency of water circulation throughout each water network

- Reduced scale-based “plaque buildup” within SWD downhole pipe infrastructure, decreasing well pressure, increasing disposal well capacity, lengthening disposal well lifespan, and therefore lowering demand for new SWDs

- Longer water storage life for recycling ponds, improving produced water reuse and recycling efficiency

- Improved recycling treatments that allow greater reuse of produced water, decreasing the demand for extraction and use of fresh groundwater from aquifers

- Improved recycling treatments that allow greater reuse of produced water, decreasing demand for permanent water disposal in disposal wells

- Elimination of solids pads in separation tanks, improving circulation efficiency, decreasing BSW impurities, and reducing the amount of toxic waste hauled to landfills

- Improved evaporation pond stability, lowering H2S levels and reducing toxic gases that limit natural evaporation processes

EK One™ Sustainability Impact

The EK One chemistry platform was developed to leverage the concept of chelation, harnessing the power of the carbon atom in revolutionary new ways. EK One chemistry “molecularly wraps” Iron (Fe), NORM, and other basic elements with carbon atoms, preventing them from initiating the adverse organic chemical reactions that create iron sulfides, TENORM, and other toxic waste by-products. As a result of EK One’s transformative approach, the Iron and other elements responsible for creation of solids are returned back into solution − where they permanently reside, along with the NORM − stable, sequestered, and forever bound within the source water.

By eliminating Iron-based reactions, EK One prevents waste solids from ever forming while simultaneously reducing corrosion and other adverse effects, revolutionizing produced water treatment. With EK One, waste remediation expenses are significantly reduced while system capacity and environmental sustainability are forever improved.

Prioritizing Safety

- All new hires are required to complete a 90-day training program.

- GPS tracking with dash camera in all vehicles to track speed, hard breaking, and excessive acceleration.

- Very strict no texting or using phone while driving policy reviewed and signed by all employees.

- Monthly random drug testing for both DOT and non-DOT employees.

- Monthly safety meeting attended by senior management.

- Zero tolerance safety violation policy–violation grounds for immediate termination.